- MDCP Home

- New Awards for 2020

- What is MDCP?

- Impact

- Reputation for Efficacy

- Important Dates/Contact

- Current ITA Project Teams

- List of All Projects

Click headers to expand:

Results & Highlights

Results & Highlights

Apply for Project Funding

Apply for Project Funding

Cooperator Project Mgt

Cooperator Project Mgt

ITA-MDCP Project Team

ITA-MDCP Project Team

Cooperator Financial Mgt

Cooperator Financial Mgt

Other MDCP Resources

Other MDCP Resources

More Resources

More Resources

Market Development Cooperator Program

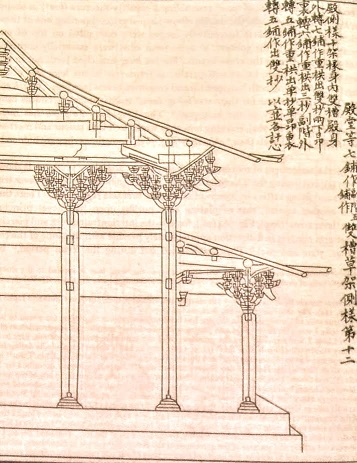

Building Code Now Allows Architects to Specify U.S.-Produced Timbers

The rafters, posts, beams, and other structural timbers pictured are from a 12th century CE building manual. Until 2017, architects in China could not designate timbers made of U.S. species. Thanks to work by the Evergreen Building Products Association (EBPA), U.S.-produced timbers can now be specified on architectural drawings in China construction projects. image: from Yingzao Fashi, by Li Jie, 1103 CE

How EBPA Helped Open the China Construction Market

It is hard for a small trade association like EBPA, based in the U.S. Pacific Northwest, to have significant influence on China's building code from afar. First, EBPA established a relationship with an expert in China. Mr. Xu Fang, a structural engineer with more than 25 years experience in wood-frame construction, is EBPA's representative in China.

Second, Mr. Fang translated design values published by Western Wood Products Association (WWPA) and other U.S. standards-developing organizations (SDOs). The Chinese Ministry of Housing and Urban-Rural Development (MoHURD) code committee will not incorporate into its building code for China design values that are not expressed in Mandarin Chinese. With the design values in the right format, Mr. Fang was able to demonstrate to MoHURD officials how the lumber grades of WWPA and other U.S.-based SDOs met the Chinese requirements for a structural material.

Third is participation in the MoHURD code committee meetings. These usually had about 20 attendees including not just MoHURD and provincial structural engineers, but also experts like Mr. Fang working to ensure that other national design values get recognized as meeting the code requirements. Other nations represented included Canada, the European Union, Japan, and New Zealand.

What's Next

A second "translation" is needed. While U.S. and other national grades and species for wooden structures are now being incorporated into China's GB50005 regulations. This publication is quite complicated. So, Mr. Fang and others on the committee are developing a design manual to help architects understand the code. The design manual breaks down the code and includes examples and diagrams.

Being able to call out a post or a joist by species, as now allowed under the revised China code, should make it easier for U.S. producers to export to China, which is already the second largest export market for U.S. softwood lumber products after Canada. But other, more sofisticated "engineered wood products" (EWP) need to find their place in the code as well. These include structural members that are glued and laminated to increase strength. "Glulam" and other EWPs are now receiving the attention of MoHURD's code committee. And EBPA's Xu Fang will be ensuring that EWPs specified on U.S. blueprints can also be specified on Chinese blueprints.

Read more about EBPA's MDCP project.

Read selected highlights of MDCP projects addressing trade barriers.

The International Trade Administration, U.S. Department of Commerce, manages this global trade site to provide access to ITA information on promoting trade and investment, strengthening the competitiveness of U.S. industry, and ensuring fair trade and compliance with trade laws and agreements. External links to other Internet sites should not be construed as an endorsement of the views or privacy policies contained therein. This site contains PDF documents. A PDF reader is available from Adobe Systems Incorporated.